Agricultural

Farming land stripping

So what is Heat Stripping?

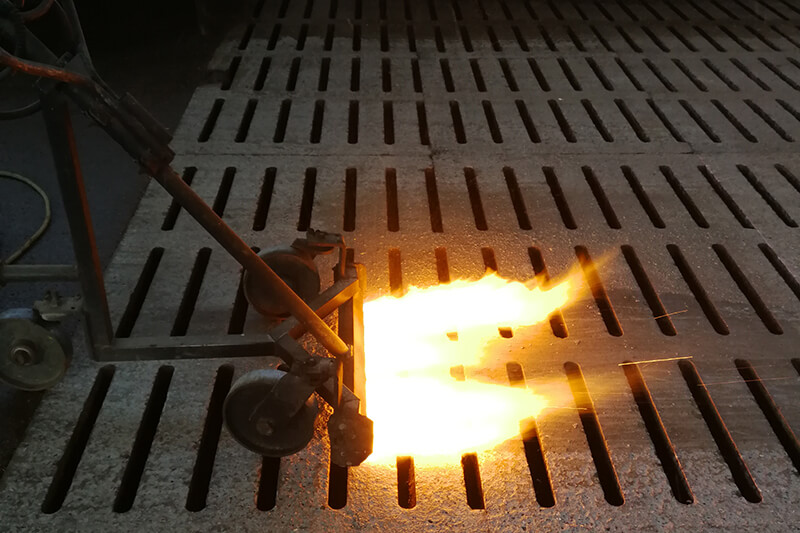

It is a cleaning concept for stables on solid or grooved concrete, perforated plates, and gratings.

The process makes easy work of obtaining a rough and flat surface. It is done by applying thermal shock from an oxy-fuel flame. The sudden energy input works on the surface and causes a striction phenomenon. It takes place without heating the material to the core so that the treated substrate is unharmed (especially the slotted edges of gratings). After treatment, the floor recovers the roughness necessary for the safe movement of animals.

What advantages does heat stripping offer the farmer?

- Treatment can be carried out anywhere, even in the places most difficult to reach (passageways, corridors, milking parlours, etc.).

- Surfacing preserves the flatness of the floor and leaves the concrete undamaged.

- Surfacing ensures thorough scraping and cleaning of the treated floors.

- Hoof hygiene is improved, and the risk of falls is eliminated.

- Surfacing dispenses with the need for post-operation treatment and little cleaning is required.

- The cost is much lower than that of mat laying.

What are the advantages of heat stripping for the animals?

The animals enjoy greater comfort and ease of movement:- There is less risk of animal falls.

- It makes it easier for the livestock to get to the trough and simplifies matters when they come on heat.

- The abrasive surface naturally erodes the hooves.

What’s the difference between grooving and scarification?

- The surface remains flat: the livestock are not unbalanced.

- Longer service life and greater efficiency.

- This process can be applied several times to the same floor slab.

- Hygiene concerns due to the maturation of manure in the grooves are a thing of the past.

The concrete is dried at depth and no longer contains grease. It is therefore impossible for it to become slippery again unless it becomes saturated again.We have many customer references.

Poultry-breeding building floor disinfection

Poultry-breeding floor disinfection

Heat disinfection eradicates most of the diseases associated with breeding buildings. It has superior results also in eliminating other insects such as the small Tenebrio (mealworm beetle), which is catastrophic for building insulation.

The application of an air-gas flame makes it possible to raise the temperature to 1950°C.

This destroys most living organisms. The moving speed of the system (from 1m/min to 3 m/min) determines the exposure time of the floor and therefore how effective the disinfection is.

Our equipment can also be used to disinfect vertical surfaces when necessary.

Currently, our machines can disinfect 4m wide strips on each pass, enabling us to work quickly (clay floors: 500 m²/h – concrete floors from 800 to 1200 m²/h depending on the maximum temperature the slab can take).

From its experience in working with flame, TOUNET has developed a specialized oven, and can provide you with a disinfection service. The service is defined in conjunction with the breeder, the cooperative and the veterinarian according to the constraints.

Disinfection is environmentally friendly, simple in its design, effective and economical. It will not damage surfaces and dispenses with the need for chemicals, making the process environmentally friendly, and it also complies with the Ecoantibio Plan.

The machine used can also be used to disinfect the surroundings of the building (provided they can be driven over).

The equipment can be mounted to pallet forks, so that farmers can perform some operations on their own.

This makes the speed of coverage greater and optimises the service cost.

Poultry-breeding building floor disinfection

Principles

This process is most often used in the poultry industry, eradicating most of the diseases affecting livestock buildings.

Heat disinfection is a process using an air-fuel flame.

On clay floors, this process is a way of maintaining a temperature of 100 °C for 1 minute to a depth of up to 3 cm.

Benefits

- Destroys most disease-causing living organisms, such as coccidia.

- Other harmful insects such as the small mealworm beetle, which is catastrophic for building insulation, are also destroyed. (1)

- The process is environmentally friendly and makes for lower chemical consumption.

- Reduced mortality rate

- Productivity gain (faster weight gain)

- Less use of antibiotics (compliance with the eco-antibio plan)

Enables us to work on every type of building.

We manufacture our own machines for heat disinfection.

We offer a disinfection service, rental of disinfection machines, and sale of this equipment.

Together with our customers, we constantly endeavour to improve the performance of our machines.

We can disinfect surface areas up to 4m wide in one pass.

(1) The harmful small mealworm beetle often causes widespread damages to farm building insulation. The mealworm beetle is also a major vector of pathogens affecting poultry, for instance, various sources of salmonella, E. coli, coronavirus…